By Paul Haslam, Technical Implementation Manager

When trying to create an optimum just in time consumable replenishment system for a business, sometimes the stock management side of things can be neglected. It’s great when the alert thresholds are set exactly where they need to be, but the system fails if there isn’t the correct consumable stock available at the right time.

Getting the consumable stock inventory levels correct where they are held within the business is a careful balancing act between holding enough stock and not holding too much which unnecessarily ties up cash.

Previously stock levels may have been calculated based on the number of certain models in the fleet and sometimes the calculations of stock requirements may have been based on “how many of these did we use in the same period 12 months ago?” This didn’t factor in things like changes to customer usage patterns / changes to the numbers of certain models in fleet, etc. which often led to incorrect stock inventory levels which is far from ideal.

There is a better way.

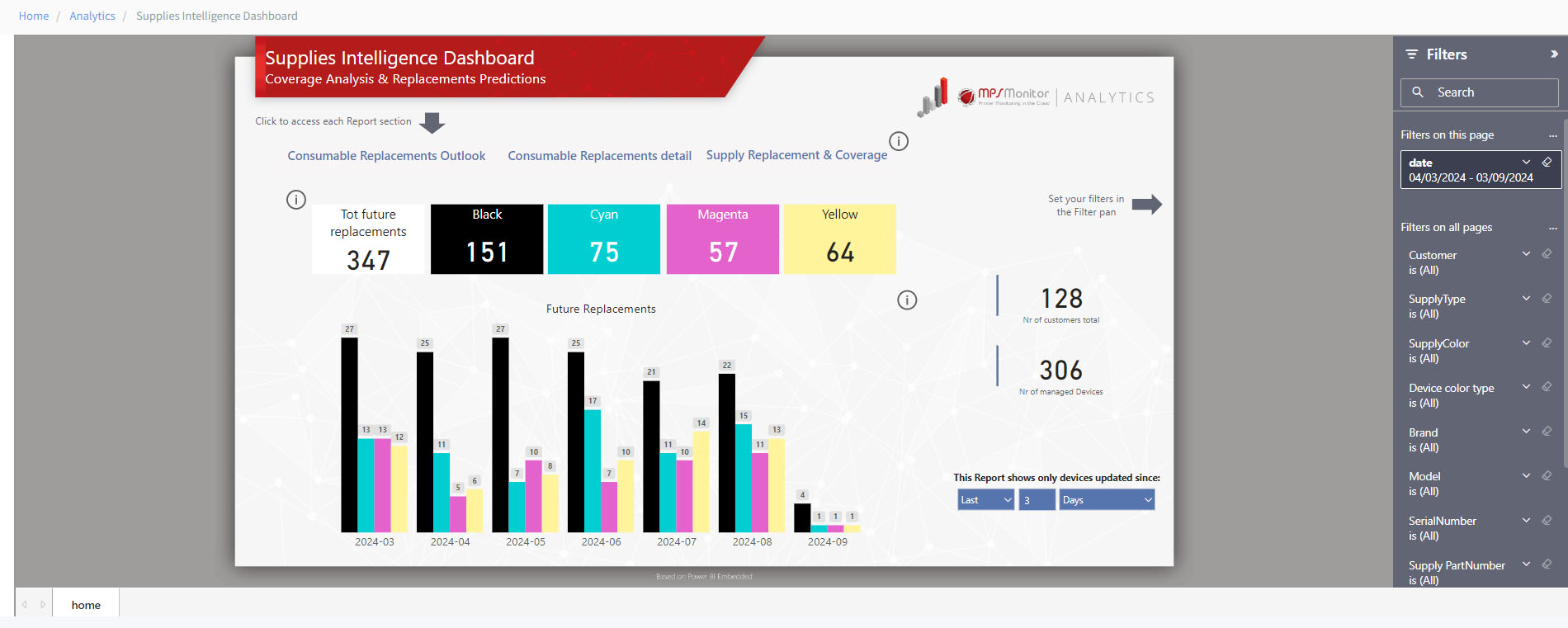

Use the data being captured from your printer fleet to show real time predictive stock requirements for specific periods.

This allows the business to ensure that the consumable stock holding is accurate so that orders can be dispatched as required to optimise the just in time delivery service, whilst also ensuring that cash flow is used optimally.

There is no need to worry about changes in usage patterns, each time a device is contacted, stock requirements are recalculated based on the latest readings.

If there are problems with certain supplies going into constraint, the business will know in advance and have time to source stock from different vendors if needed.

Let technology do the work, no more trying to remember what you did previously and basing things on data that may no longer be accurate.

Use case – Transforming consumable stock management with predictive analytics

Challenges faced by a Managed Print Dealer and how they can be addressed

Company A holds approximately £750,000 of consumable stock to service a fleet of 6,500 devices.

- The stock levels were based on the previous stock levels for the last 12 months so weren’t taking into account changes in usage patterns or differences to the models in fleet.

- The consumables were picked by a team who never knew from day to day the volume of consumable requests and consumables were picked by hand with no cross-checking of what was picked.

An analysis of the situation found that:

- Some items of consumable stock had remained in the warehouse for in excess of 18 months (aged stock)

- There were often shortages of certain consumable part codes to fulfil orders

- The just in time delivery service had to be kept at sub-optimal lead times to allow time for stock shortages to be addressed

- Stock was ordered from distributors for which a delivery cost was paid and a further delivery cost was then incurred when the consumable was actually despatched from the warehouse

- Consumable stock occupied approximately 20% of the total warehouse space

- The team who picked the consumables were always expected to pick all the orders, there was no consideration given to workload, illness or holidays

- Mis-picks of consumable part codes was commonplace, especially when there were lots of orders on the same day, leading to increased administrative effort and cost

- Incorrect delivery labels were attached to items of stock, causing the wrong consumable to be sent to the wrong place, leading to increased administrative effort and cost

- Sometimes due to the sheer volume of orders on a particular day, not all orders were processed that day, leading to devices running out of a particular consumable

How this was addressed:

Stage 1

- Using Predictive Analytics, consumable stock inventory levels were adjusted to forecasted demand leading to elimination of all aged stock and ensured that stock was available for orders

- Where there was an issue with consumable stock – for example a supply constraint, the stock controller would know in advance and had time to source stock from elsewhere

- The Just in time delivery service could be run at optimal levels as there was always stock available to fulfil orders.

Stage 2

- Using Predictive Analytics to provide the forecasted demand, all the consumable stock was moved to a distributor

- The distributor provided a facility whereby the consumable stock forecast was used to allocate that stock to the dealer to fulfil orders when received

- Where potential stock shortages were identified, the dealer had the option to source the stock from elsewhere and service a small number of orders from the warehouse as previously

- The distributor guaranteed that any order received up to 17:45 each day would be processed, picked and packed for delivery the next day

- The distributor provided electronic checking of picked orders to ensure any mis-picks were eliminated from the consumable resupply service

- The just in time delivery service could remain at optimal levels as there was always stock available for orders

- Orders were sent direct from the distributor, eliminating an additional delivery cost and improving the carbon footprint of the consumable resupply service

- Warehouse space at the dealer was freed up

- The team who picked and packed the consumables previously at the dealer had only the occasional consumable order to pick and pack in response to stock shortages at the distributor where alternative stock was sourced.

If you want to learn more about how you can benefit from predictive analytics by using MPS Monitor platform, don’t hesitate to contact us!